Long experience over multiple industries.

We have successfully sampled in various industries such as the Metallurgical, Energy, Petroleum Products, Glass, Cement, Wood Production, Automotive, Food Products, Chemical Processing and Thermal Treatment industry.Why choose Us

We are committed to providing quality solutions that meet specific needs.We maintain high standards of professional conduct and comply with local and international regulations. This means that you can entrust all your emission testing needs to us.

Our Vision

The founders of Future Projects believe that this company will become one of the largest and most respected emission monitoring companies. Future Projects will achieve this by utilising the following core principles: scientific expertise, technical expertise, a cost-effective approach and a commitment to continuing education.

Our Values

Integrity

Diligence

Accountability

Discipline

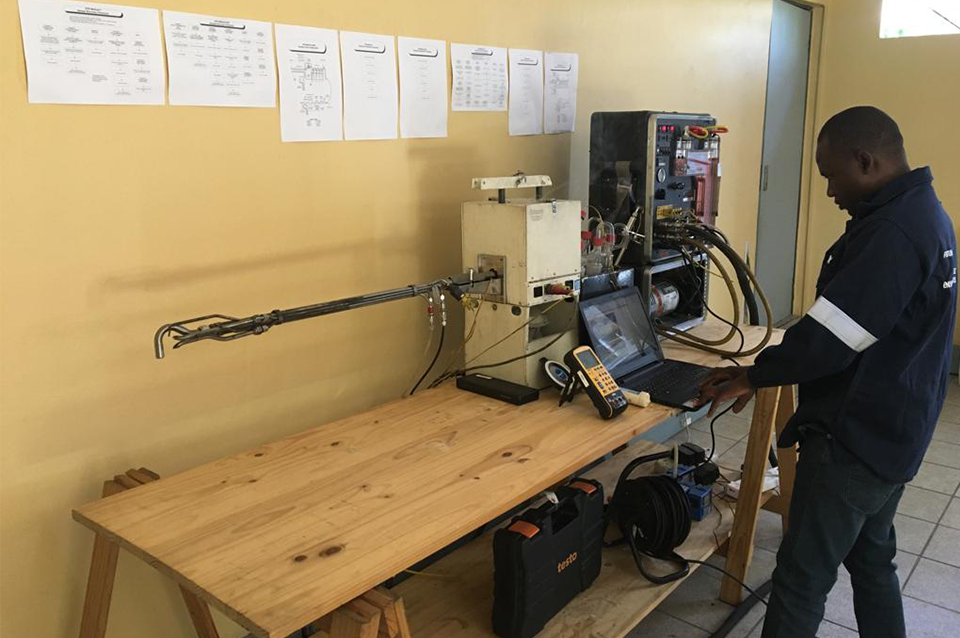

Flow, temperature and velocity measurements:

By making use of US EPA method 2, Future Projects is able to determine the average stack gas velocity by measuring the gas density and average velocity head using Type S pitot tubes. Measuring equipment includes: liquid manometer, Type S calibrated pitot tubes as well as type K thermocouples, dry gas meter and gas analyser.

All sampling methodologies applied by Future Projects are aligned with the requirements of the South African Minimum Emission Standards.

VOCs (volatile organic compounds) concentrations: :

The sampling techniques applied are based on US EPA sampling methodologies. In order to quantify the organic compounds concentrations, a sample is drawn from the source into an inert sampling bag. The sample is then passed over an absorptive medium, specifically chosen to maximise the recovery of the various organic constituents from the sampling media when analysed by GC-MS (Gas Chromatography Mass Spectrometry).

Source emissions sampling:

Future Projects enable clients to meet their environmental emission reporting requirements stipulated in their Atmospheric Emissions Licenses (AEL).

All sampling methodologies applied by Future Projects are aligned with the requirements of the South African Minimum Emission Standards.

Dust Fallout Monitoring

It is a process of measuring dust fallout on a continuous basis by application of “ASTM D1739” sampling methodology. ASTM D1739 is an American Standard for Testing Material which is the standard test method for the collection and measurement of dust fall.

Efficiency testing for abatement technology devices

It is a sampling campaign designed to determine the efficiency of the abatement equipment to confirm if the equipment is still meeting the recommended specifications from manufacturer.

This type of testing often involves two or more sampling teams performing simultaneously measurements at the inlet and outlet ductings of the abatement devices such as ESP (Electro Static Precipitator), Scrubber, Absorber, Incinerators…